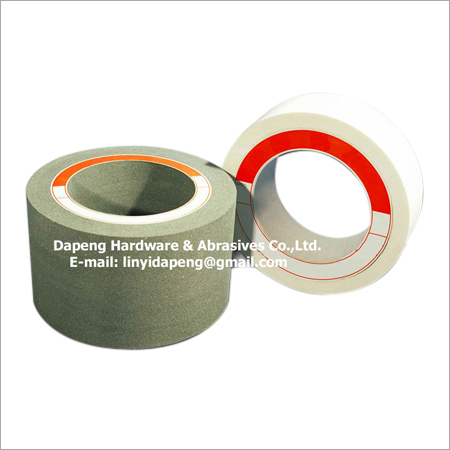

Surface Grinding Wheel

Surface Grinding Wheel Specification

- Backing

- None

- Bonding

- Vitrified Bond

- Shape

- Cylindrical

- Hardness

- Medium to Hard

- Chemical Composition

- Al2O3, SiO2, Fe2O3, TiO2

- Grain Type

- A (Aluminium Oxide)

- Toughness

- High

- Material

- Aluminium Oxide

- Type

- Surface Grinding Wheel

- Grain Sizes

- 24, 36, 46, 60, 80, 100

- Rolls Size

- 355 mm x 38 mm x 127 mm

About Surface Grinding Wheel

We are recognized as the prominent manufacturer, exporter and supplier of a wide array of Air Surface Grinding Wheel that is widely used in different types of surface grinding applications. Made available in a spectrum of specifications, this wheel is manufactured using high quality raw materials and pioneering technology under the able guidance of our dextrous professionals. Besides, our valuable customers can purchase this Air Surface Grinding Wheel from us at reasonable prices with no hassle.

Key Features:

- Excellent strength

- Low friction

- Ruggedness

- Fine Finish

Our grinding wheels (diameter less than 1100mm),we have vitrified bonded,resin bonded and rubber bonded wheels,

Surface Grinding Wheels, Toolroom Wheels, Centerless Wheels, Crankshaft Wheels, Cylindrical Wheels, Disc Grinding Wheels, Regulating Wheels, Roll Grinding Wheels, Grinding Segments, and etc.

- Diameter: 10mm ~ 1100mm

- Thickness: 3mm ~ 600mm

- Materials: A (brown aluminum oxide), WA (white aluminum oxide), PA (pink aluminum oxide), GC (green silicon carbide), C (black silicon carbide)

- Grit Size: 24,36,46,60,80,100,120,180,240,320

Bond Type

- Vitrified Bonded (V)

- Resin Bonded (B)

- Rubber Bonded (R)

High Performance Material

The wheel is crafted from aluminium oxide (A grain type), combined with SiO2, Fe2O3, and TiO2, guaranteeing high toughness and durability. Its vitrified bond offers stability and longevity during rigorous grinding processes. Such chemical composition ensures the surface grinding wheel maintains its integrity even under intense operating conditions.

Versatile Grain Sizes

Available in grain sizes 24, 36, 46, 60, 80, and 100, the grinding wheel adapts to a variety of surface finish requirements. Coarser grains are perfect for rapid material removal, while finer grains deliver smoother finishes. This versatility makes it effective for both heavy stock removal and precision finishing tasks.

Export Quality Manufacturing

Manufactured in China, this surface grinding wheel is rigorously tested to meet international standards. As an exporter, manufacturer, and supplier, the company delivers reliable products suitable for global markets, ensuring consistent quality and competitive pricing for industrial clients.

FAQs of Surface Grinding Wheel:

Q: How is the surface grinding wheel used in industrial applications?

A: The surface grinding wheel is employed for precise material removal and surface finishing on metal workpieces. Its cylindrical shape and range of grain sizes allow it to handle both coarse grinding and fine finishing, making it valuable in machine shops, production facilities, and fabrication units.Q: What process is involved in manufacturing the surface grinding wheel?

A: The manufacturing process involves mixing aluminium oxide with additives such as SiO2, Fe2O3, and TiO2, forming the wheel into a cylindrical shape, and bonding it using a vitrified process. This results in a hard, tough grinding tool suitable for demanding applications.Q: When should I select a specific grain size for my grinding task?

A: Choose a lower grain size (24, 36) when aggressive material removal is needed, and opt for higher grain sizes (80, 100) for achieving finer, smoother finishes. Grain selection depends on the surface requirements and the material being processed.Q: Where is this surface grinding wheel manufactured and exported from?

A: This grinding wheel is manufactured, supplied, and exported from China, adhering to international quality standards to serve global industrial clients.Q: What are the benefits of using a vitrified bond in this grinding wheel?

A: The vitrified bond provides excellent strength and porous structure, enabling efficient coolant flow and heat dissipation. This results in minimal thermal damage to workpieces and extends the wheels operational life.Q: What kinds of materials can be processed with this surface grinding wheel?

A: Predominantly designed for metals and hard alloys, the wheel is especially effective on ferrous materials thanks to its hardness and high toughness, but its also suitable for selected non-ferrous metals depending on grinding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Regulating Grinding Wheels

Shape : Round

Hardness : Soft to Medium

Material : Aluminium Oxide / Silicon Carbide

Grain Sizes : 80 grit to 320 grit

Backing : Reinforced Cloth

Bonding : Resin Bond

Centerless Grinding Wheels

Shape : Round / Wheel

Hardness : From N (Medium) to R (Hard)

Material : Abrasive Grain + Bonded Matrix

Grain Sizes : 46 Grit to 180 Grit

Backing : N.A. (Solid Wheel)

Bonding : Vitrified, Resin Bonded

Toolroom Grinding Wheel

Shape : Straight, Cylindrical, Dish, Cup

Hardness : Soft, Medium, Hard

Material : Aluminum Oxide, Silicon Carbide

Grain Sizes : Fine, Medium, Coarse (24 to 120 grit)

Backing : None

Bonding : Vitrified, Resin bond

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry