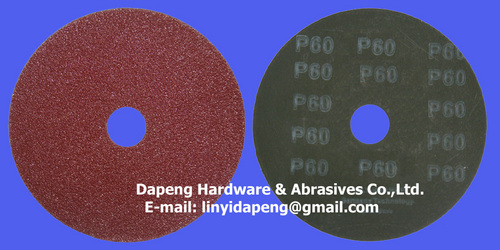

Fibre Discs

Fibre Discs Specification

- Chemical Composition

- Cellulose fibre backing with synthetic resin and abrasive grains

- Hardness

- Medium to Hard

- Bonding

- Phenolic Resin Bond

- Shape

- Round Disc

- Type

- Resin Bonded Fibre Disc

- Grain Sizes

- 24, 36, 60, 80, 100, 120, 150

- Rolls Size

- 178 mm, 180 mm, 200 mm, 230 mm, 250 mm, Custom sizes available

- Strips Size

- Standard: 20 mm up to 80 mm; custom widths on request

About Fibre Discs

We are considered as one of the leading manufacturers, exporters and suppliers of optimum quality Fibre Discs. The provided disc is manufactured by making use of advanced technology and premium quality fiber by our skilled team of professionals. Offered disc is widely used for removing rust from metal and nonmetal surface, grinding melding seams, polishing, removing burr, etc. Deliver after testing it on different parameters to assure its quality, we provide this Fibre Discs to the clients at nominal prices.

Key Features:

- Sturdiness

- Perfect finish

- Highly efficient

- Robust design

Other Information:

- A kind of lame lla abrasive, which is formed by bonding the abrasive on the vulcanized fiber disc backing with resin.

Applications

- It is mainly used for removing rust from metal and nonmetal surface, grinding melding seams, polishing, removing burr, etc.

- It is wildly used in auto, aviation, machinery, instrument, bridge, construction, etc.

- 100 x 16mm

- 115 x 22mm

- 125 x 22mm

- 150 x 22mm

- 180 x 22mm

Grit Size: P20# ~ P240#

Versatile Size Options for Every Application

From 178 mm up to 250 mm, including custom sizes, our fibre discs can be tailored to fit diverse machinery setups. Whether your task requires standard or bespoke dimensions, we ensure compatibility and flexibility, making our products suitable for a wide range of industrial processes.

Superior Bond Strength and Hardness

Crafted with phenolic resin bonding, our discs possess medium to hard levels of hardness. This guarantees durability and maintains consistent performance during heavy-duty grinding or sanding. You can rely on their stability for demanding environments.

Optimal Grain Selection for Quality Results

With abrasive grain sizes ranging from 24 to 150, our discs provide the right texture for various surface finishes. Whether you need coarse removal or fine polishing, choose the suitable grain to match your requirements and ensure effective material treatment.

FAQs of Fibre Discs:

Q: How are the resin bonded fibre discs used in industrial operations?

A: They are primarily utilized for grinding, sanding, and surface finishing on metals, wood, or composites in manufacturing, fabrication, and maintenance facilities.Q: What grain sizes are available, and how do I choose the right one?

A: Grain sizes offered are 24, 36, 60, 80, 100, 120, and 150. Coarser grains (lower numbers) are ideal for rapid material removal, while finer grains (higher numbers) work well for smoothing and finishing applications.Q: When should I opt for custom disc sizes or strip widths?

A: Custom sizes or widths are recommended when standard dimensions (178 mm to 250 mm and 20 mm to 80 mm strips) dont fit your equipment or process requirements. We offer customization to ensure optimal compatibility.Q: What is the process for ordering as an international customer?

A: As an exporter, manufacturer, and supplier in China, we facilitate global orders. Contact our sales team with specifications or requirements; we provide quotations, ship internationally, and support customized solutions.Q: Where are these fibre discs typically manufactured and exported from?

A: These discs are manufactured at our facilities in China, from where we supply and export to international markets across various industries.Q: What are the main benefits of using cellulose fibre backed, resin bonded discs?

A: They deliver excellent strength, resilience, and uniform abrasive distribution. This results in consistent performance, longer lifespan, and efficient material processing with reduced downtime.Q: How does phenolic resin bonding enhance disc hardness and durability?

A: Phenolic resin forms a robust bond between backing and abrasive grains, contributing to medium to hard hardness levels. This ensures the discs withstand heavy loads and prolonged usage in industrial settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry