Abrasive Velcro Discs

Abrasive Velcro Discs Specification

- Shape

- Round Disc

- Toughness

- High

- Hardness

- Medium to Hard

- Chemical Composition

- Al2O3, phenolic resin, cellulose backing

- Bonding

- Resin over Resin

- Material

- Aluminum Oxide

- Grain Sizes

- P40, P60, P80, P100, P120, P150, P180, P220

- Rolls Size

- 115 mm, 125 mm, 150 mm, 180 mm (diameter)

- Strips Size

- Custom/On Request

About Abrasive Velcro Discs

Fostered with a team of highly qualified professionals, we have been able to manufacture, export and supply a broad range of Abrasive Velcro Discs. The provided disc is widely used for the polishing of automobile, surface and old paint, wood, stone, metal, etc. Available in diverse specifications to meet clients' specific needs, the disc provided by us is manufactured using superior quality velcro and pioneering technology at par with set industry norms. Clients can purchase this Abrasive Velcro Discs from us at pocket friendly prices.

Key Features:

- Rugged construction

- Sturdiness

- Accurate dimensions

- Durability

Specifications:

- It is pasted up hard rubber disc of pneum-atic or electric machinery.

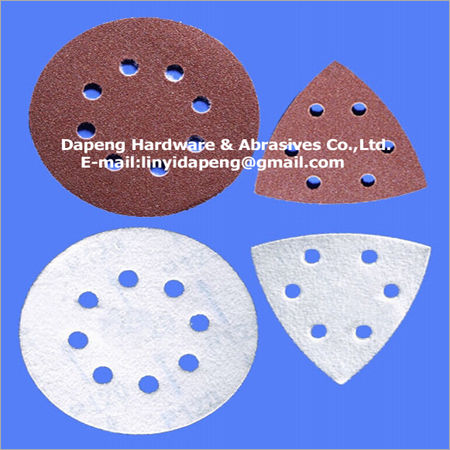

- It can be punched to circular, triangle, or other special shapes.

- 6 holes and 8 holes, or without hole

Size: 100mm,115mm,125mm,150mm,180mm

Grit Size: P20 ~ P400

Versatile Grain Selection

Abrasive Velcro Discs are supplied in grain sizes ranging from P40 for aggressive material removal to P220 for fine finishing. This broad selection ensures compatibility with different sanding requirements, making these discs a dependable choice for woodworking, metalworking, and surface preparation across industries.

Superior Construction & Durability

Each disc is constructed using aluminum oxide, renowned for its hardness and longevity. Combined with resin over resin bonding and a cellulose backing, these discs offer high toughness, preventing premature wear and supporting extended usage even in demanding environments.

Custom Sizing & Flexible Use

While the standard shapes are round with various diameters, we also accommodate custom strip sizes upon request. This adaptability suits specialized machinery and unique project specifications, adding convenience for manufacturers or operators seeking tailored solutions from a reliable Chinese exporter.

FAQs of Abrasive Velcro Discs:

Q: How do I select the right grain size for my sanding project with these Velcro discs?

A: Choose a coarser grain like P40 or P60 for rapid material removal or heavy-duty sanding. For intermediate smoothing, opt for P80 to P120. Finer grains such as P150 to P220 are ideal for final finishing and preparing surfaces for painting or varnishing.Q: What are the main benefits of using aluminum oxide Velcro discs with resin over resin bonding?

A: Aluminum oxide is known for its high toughness and cutting efficiency, making it suitable for a broad range of surfaces. The resin over resin bonding increases the discs durability, preventing early breakdown and delivering a stable performance even in rigorous applications.Q: When should I use a medium to hard abrasive disc versus a softer one?

A: Medium to hard abrasive discs are recommended when you require aggressive material removal, consistent wear, and longer disc life. They are well-suited for sanding harder materials like metals or hard woods, as well as for continuous industrial use.Q: Where can these abrasive Velcro discs be effectively used?

A: These discs are ideal for use in woodworking shops, metal fabrication facilities, automotive body shops, and general industrial environments where efficient and reliable sanding is required.Q: How can the Velcro backing improve my sanding process?

A: The Velcro (hook-and-loop) backing enables quick and easy disc attachment and removal, reducing downtime and making grit changes more convenient during multi-step sanding tasks. This increases overall work efficiency and minimizes delays.Q: What is involved in custom ordering strip sizes or specific diameter discs?

A: Simply provide your preferred measurements and specifications when placing an order. As a manufacturer and exporter based in China, we can accommodate unique requests for non-standard strip sizes or tailored disc diameters, ensuring they suit your machinery or process needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry