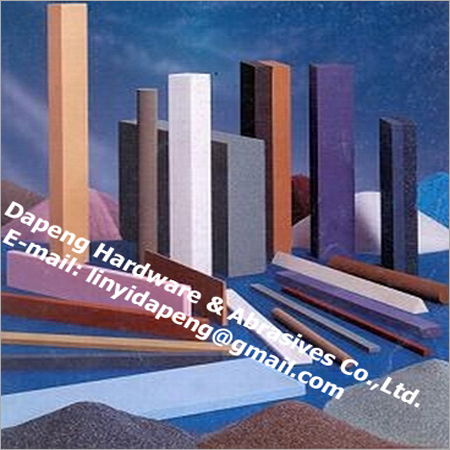

Honing Stick

Honing Stick Specification

- Material

- Abrasive Stone

- Processing Type

- Precision Grinding

- Condition

- New

- Technology

- Honing

- Dimension (L*W*H)

- Standard / Customizable

- Power Mode

- Manual / Machine Compatible

- WorkingSpeed

- Up to 1800 RPM

- Application

- Cylindrical Honing, Industrial Surface Finishing

- Coating Type

- Vitrified / Resin Bonded

About Honing Stick

We have emerged as the leading manufacturer, exporter and supplier of a wide variety of Honing Stick. Offered stick is precisely manufactured under the direction of dexterous professionals using quality tested raw materials and cutting-edge technology at par with international quality standards. The provided stick is used for machining cast iron parts, engine cylinder, hydraulic & pneumatic cylinders and other components for the automobile industry. This stick is verified upon various parameters to assure its durability. Clients can purchase this Honing Stick from us at pocket friendly rates.

We manufacture & supply a quality line of Honing Stick, which is made to offer desired results. It helps ensure excellence in production, short processing time and long life of the materials. The results are faster cutting rate, less dressing involved and cost-effectiveness. Also, our Honing Sticks are designed to give a better finish to the components. These are effective for many applications, including cast iron, carbide honing, super finishing, alloy applications, and non ferrous products. We meet your general purpose as well as special honing need, effectively.

Features & Benefits:

- Strong, reliable & versatile

- High life output

- Low cost for components

- Fast rate & consistent finish

Other Information:

- Applications: it is suitable for easy cleaning of rough castings,gear deburring, edge honing of cutting tools.

- Also honing stick with sulfur for more hardness.

Popular Size

- 100 x 6 x 6mm,

- 100 x 8 x 8mm,

- 100 x 10 x 10mm,

- 100 x 12 x 12mm,

They also can be supplied in required sizes,materials, grit sizes and types.

Engineered for Precision Grinding

Our honing sticks are meticulously crafted using high-quality abrasive stone to guarantee accuracy in precision grinding and surface finishing. Whether you require standard sizes or have custom specifications, our sticks can be tailored to meet your unique industrial needs.

Versatile Power Compatibility

Designed for both manual and machine use, these honing sticks offer remarkable flexibility. Their compatibility allows seamless integration into different honing setups, enhancing efficiency while maintaining optimal performance at working speeds up to 1800 RPM.

Advanced Surface Finishing Applications

Ideal for cylindrical honing, our sticks are invaluable for industrial surface finishing tasks. The choice of vitrified or resin-bonded coatings extends their functionality, supporting a variety of materials and requirements in demanding manufacturing environments.

FAQs of Honing Stick:

Q: How can I use the Honing Stick for cylindrical honing applications?

A: The Honing Stick can be deployed in manual or machine-driven honing setups. Simply select the stick dimension suitable for your cylinder, install it correctly, and operate at speeds up to 1800 RPM for optimal material removal and surface finish.Q: What materials are used in manufacturing the Honing Stick?

A: These honing sticks are constructed from premium abrasive stone, with advanced vitrified or resin-bonded coatings, enhancing their durability and precision for industrial grinding and finishing tasks.Q: When should I choose a custom dimension for my honing stick?

A: Opt for a custom dimension when your application requires precise fitting or unique size specifications not covered by standard products. Custom options ensure seamless integration into specialized manufacturing processes.Q: Where are your honing sticks manufactured and supplied from?

A: Our honing sticks are manufactured, exported, and supplied directly from our facilities in China, ensuring strict quality control and timely international delivery to meet global industrial needs.Q: What is the typical process of precision grinding with this honing stick?

A: Precision grinding involves mounting the honing stick in the honing device, applying it at specified pressures and speeds, and using the stick to evenly grind and finish cylindrical surfaces, resulting in superior dimensional accuracy and surface quality.Q: How can I benefit from the vitrified or resin-bonded coatings?

A: Vitrified and resin-bonded coatings offer enhanced wear resistance, consistent abrasive action, and prolonged tool life, making them ideal choices for both high-volume production and demanding material finishing tasks.Q: What are the main applications for this honing stick in industrial environments?

A: The honing stick excels at cylindrical honing, surface finishing, and fine grinding. It is widely used in automotive, aerospace, hydraulic, and general manufacturing sectors to achieve smooth, accurate, and high-quality component surfaces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry