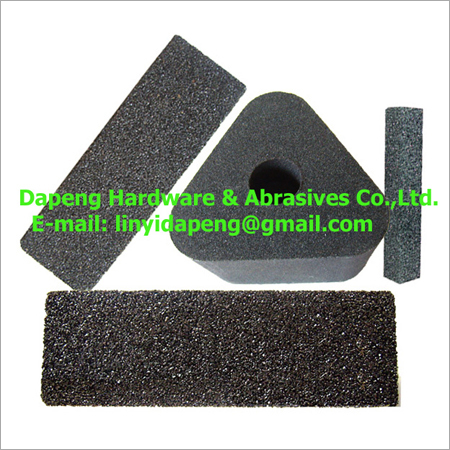

Rubbing Brick

Rubbing Brick Specification

- Connectivity Type

- None

- Features

- High durability, High abrasion resistance, Easy to grip

- Control System

- None

- Accessories

- None

- Power Source

- Manual

- Material

- Silicon Carbide

- Type

- Rubbing Brick

- Condition

- New

- Fuel Type

- None

- Use

- Surface Finishing, Smoothing Concrete, Stone, Masonry

- Cleaning Process

- Manual

- Cleaning Type

- Surface Cleaning

About Rubbing Brick

We have marked a distinct position in the domain by manufacturing, exporting and supplying a premium quality range of Rubbing Brick. Our offered brick is basically used for cutting, polishing and smoothing floor corner, side walls, iron, steel cast iron surfaces and more. This brick is manufactured under the direction of skilled professionals at our sophisticated production unit using the finest quality raw materials and advanced technology in adherence with international quality standards. Moreover, offered Rubbing Brick can be easily availed from us at industry leading rates.

Key Features:

- Rugged design

- Impact resistance

- Easy to install

- High strength

| Size | 4" x 2" x 2" | 100 x 50 x 50mm | Rectangular |

| 6" x 2" x 2" | 150 x 50 x 50mm | Rectangular | |

| 8" x 2" x 2" | 200 x 50 x 50mm | Rectangular | |

| 4" x 1" x 1" | 100 x 25 x 25mm | dressing | |

| 6" x 1" x 1" | 150 x 25 x 25mm | stick | |

| 75 x 50 x 20mm | | Triangle | |

| Material | A (brown aluminum oxide), WA (white aluminum oxide) | ||

| C (black silicon carbide), GC (green silicon carbide) | |||

| Grit size | 20#,24#,36#,46#,60#,80#,100#,120#,180#,240#... | ||

They also can be supplied in required sizes,materials, grit sizes and types.

Superior Rubbing Brick for Professional Surface Care

Experience unmatched performance with our silicon carbide rubbing brick, designed for professionals who demand reliability. Its high abrasion resistance and sturdy grip facilitate smooth, efficient surface preparation and finishing for concrete, stone, and masonry. This hand-held brick ensures consistent results, making it indispensable for contractors, masons, and renovators seeking optimal outcomes without power tools.

Optimized Manual Cleaning Solution

Our rubbing brick is tailored for manual use, eliminating the need for power sources, accessories, or control systems. Its ergonomic design guarantees ease of handling and reduces user fatigue. Whether it is for surface smoothing, cleaning, or removing irregularities in construction, this product promises both effectiveness and longevity in every application.

FAQs of Rubbing Brick:

Q: How is the silicon carbide rubbing brick used for surface finishing?

A: The silicon carbide rubbing brick is manually applied directly onto concrete, stone, or masonry surfaces. By rubbing it in a back-and-forth motion, users can smooth rough patches, clean debris, or prepare surfaces for further finishing without requiring any power tools or accessories.Q: What materials can be cleaned or finished using this rubbing brick?

A: The rubbing brick is ideally suited for concrete, stone, and masonry. Its high abrasion resistance makes it effective in smoothing, cleaning, or finishing these hard surfaces both in new construction and restoration tasks.Q: When should I use a rubbing brick instead of powered tools?

A: A rubbing brick is perfect for jobs where precision and manual control are essential, or in areas where electricity is unavailable. Its also beneficial for small-scale surface corrections, edge smoothing, and final touches after major work with power tools.Q: Where is this product manufactured and supplied from?

A: This silicon carbide rubbing brick is produced and distributed by experienced exporters, manufacturers, and suppliers based in China, ensuring global reach and reliable product quality.Q: What are the main benefits of using a silicon carbide rubbing brick?

A: The rubbing brick delivers superior durability and resistance to wear, provides an excellent grip for comfort and safety, and operates entirely manuallyoffering versatility and independence from electrical sources or consumable parts.Q: Can you describe the typical process of using this brick for surface cleaning?

A: Manual cleaning involves applying steady, even pressure while moving the brick across the target surface. The abrasive nature of silicon carbide facilitates the removal of stubborn material, residues, or surface irregularities, restoring the desired finish with minimal effort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry