Regulating Grinding Wheels

Regulating Grinding Wheels Specification

- Hardness

- Soft to Medium

- Toughness

- High

- Backing

- Reinforced Cloth

- Chemical Composition

- Standard Abrasive Mixture

- Bonding

- Resin Bond

- Shape

- Round

- Grain Type

- Coarse / Fine

- Material

- Aluminium Oxide / Silicon Carbide

- Type

- Regulating Grinding Wheel

- Grain Sizes

- 80 grit to 320 grit

- Rolls Size

- 150 mm to 500 mm

- Strips Size

- Customizable as per requirement

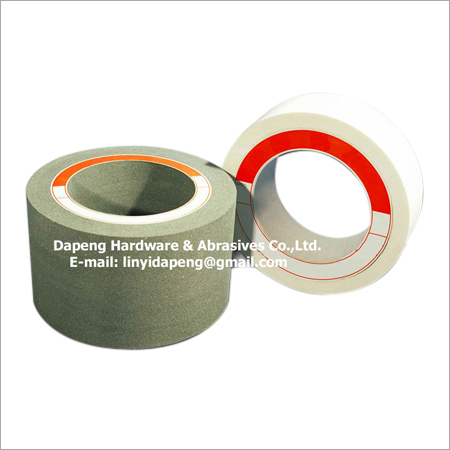

About Regulating Grinding Wheels

Owing to the expertise of our highly experienced professionals, we are able to manufacture, export and supply superior quality Regulating Wheel. The provided wheel is manufactured using quality examined raw materials with the aid of advanced technology in adherence with set industry standards. The wheel provided by us is widely used in centerless grinding as a control and feed wheel. Moreover, clients can purchase these Regulating Wheel from us at market leading prices.

Key Features:

- Flawless finish

- Easy to install

- Dimensional accuracy

- Long life

Specification:

- Better resiliency: Better surface finish, Reduces chatter tendency, Greater shock absorption

- Better gripping power: Less slippage, Dimensional accuracy, Less rejection

| Popular Size | 230 x 100 x 76.2mm | A 80 LR T1 |

| 230 x 150 x 76.2mm | A 80 LR T1 | |

| | | |

| 300 x 150 x 127mm | A 80 RRE | |

| RBS 200 x 40mm | | |

| | | |

| 300 x 20 x 127mm | A 80 RRE | |

| RBS 200 x 40mm | |

Materials: A (brown aluminum oxide), WA (white aluminum oxide), GC (green silicon carbide), C (black silicon carbide)

They also can be supplied in required sizes,materials, grit sizes and types.

Optimized Performance and Versatility

The regulating grinding wheels are engineered to provide reliable performance across diverse grinding applications. With a choice of grain sizes ranging from 80 grit to 320 grit and customizable strip sizes, users can achieve precise results tailored to their requirements. The wheels reinforced backing and high toughness ensure longevity and consistent productivity, making them suitable for a variety of industrial processes.

Quality Assurance and Customization

Each wheel is manufactured under stringent quality controls using standard abrasive mixtures and resin bonding techniques. Our flexibility in size, strip dimensions, and grain types allows customization according to specific client needs. As leading suppliers, manufacturers, and exporters from China, we guarantee premium products and robust support for international customers.

FAQs of Regulating Grinding Wheels:

Q: How are regulating grinding wheels utilized in industrial processes?

A: Regulating grinding wheels are primarily used to control the speed and direction of workpieces during centerless grinding processes. Their durable construction and customizable features make them ideal for achieving precise finishes and maintaining consistent quality in various applications.Q: What materials are used in the construction of these grinding wheels?

A: These wheels are manufactured using Aluminium Oxide or Silicon Carbide, both known for their high abrasion resistance and toughness. The reinforced cloth backing and resin bond further enhance durability and adherence of abrasive grains.Q: When should different grain sizes be selected for grinding applications?

A: Coarse grain sizes, such as 80 grit, are suitable for rapid material removal and rough grinding. Fine grains, like 320 grit, are recommended for finishing operations and achieving smoother surfaces. The choice depends on the specific surface requirements and production goals.Q: Where can these grinding wheels be sourced?

A: We supply, manufacture, and export these regulating grinding wheels directly from China. International clients can contact our sales team for customized orders or queries regarding technical specifications.Q: What is the process involved in manufacturing these wheels?

A: The manufacturing process involves blending standard abrasive mixtures with resin, forming the wheel to the desired round shape and size, and reinforcing it with cloth backing. Each wheel undergoes strict quality checks to ensure optimal hardness, toughness, and performance.Q: How does resin bonding benefit the grinding wheels performance?

A: Resin bonding provides enhanced flexibility and shock resistance, allowing the wheel to retain abrasive grains while maintaining structural integrity under various operational stresses. This results in a longer wheel life and consistent grinding efficiency.Q: What are the advantages of customizable strip and wheel sizes?

A: Customizable strips and wheel sizes enable users to match the grinding tool to specific machine setups and process requirements, optimizing material removal rates and surface finishes according to individual project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Flexible Grinding Wheel

Minimum Order Quantity : 50 Pieces

Hardness : Yes

Type : Flexible Grinding Wheel

Shape : Round

Material : SS

Ball Grinding Wheel

Minimum Order Quantity : 3 Pieces

Hardness : Hard

Type : Ball Grinding Wheel

Shape : Round

Centerless Grinding Wheels

Hardness : From N (Medium) to R (Hard)

Type : Centerless Grinding Wheel

Shape : Round / Wheel

Material : Abrasive Grain + Bonded Matrix

Chemical Composition : Abrasives, Binders, Fillers

Toolroom Grinding Wheel

Hardness : Soft, Medium, Hard

Type : Toolroom Grinding Wheel

Shape : Straight, Cylindrical, Dish, Cup

Material : Aluminum Oxide, Silicon Carbide

Chemical Composition : Al2O3, SiC, bonding agents

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry