Cylindrical Grinding Wheel

Cylindrical Grinding Wheel Specification

- Bonding

- Vitrified or Resin Bonded

- Shape

- Cylindrical

- Hardness

- H to N (varies by application)

- Grain Type

- Coarse, Medium, Fine

- Chemical Composition

- Al2O3 or SiC with vitrified or resin bond

- Backing

- None

- Toughness

- High

- Material

- Abrasive (Aluminum Oxide or Silicon Carbide)

- Type

- Cylindrical Grinding Wheel

- Grain Sizes

- 24 to 120 Grit

- Rolls Size

- Customizable as per requirement

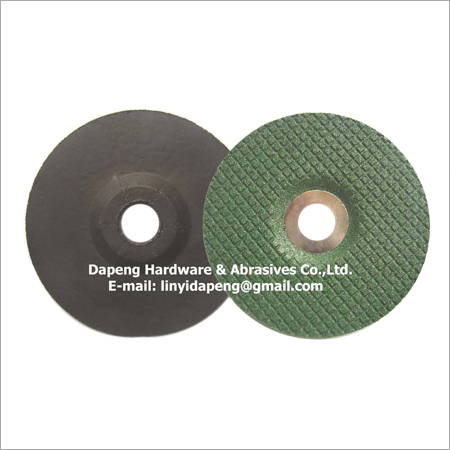

About Cylindrical Grinding Wheel

Backed by rich industry understanding, we have been able to manufacture, export and supply an optimum quality range of Cylindrical Grinding Wheel. Made available in various specifications as per the varied necessities of the clients, this wheel is intricately manufactured using quality approved raw materials and contemporary technology. Offered wheel is primarily used for grinding and processing all kinds of bearing groove. Moreover, we provide this Cylindrical Grinding Wheel at highly competitive prices to the clients.

Key Features:

- Sturdy construction

- Abrasion resistance

- Flawless finish

- High strength

Specification:

300 x 8 x 127mm

300 x 10 x 127mm

300 x 12 x 127mm

300 x 14 x 127mm

300 x 16 x 127mm

350 x 10 x 127mm

350 x 12 x 127mm

350 x 14 x 127mm

350 x 16 x 127mm

350 x 18 x 127mm

350 x 20 x 127mm

400 x 12 x 127mm

400 x 14 x 127mm

400 x 16 x 127mm

400 x 18 x 127mm

400 x 20 x 127mm

They also can be supplied in required sizes, materials, grit sizes and types.

Precision Tailored for Industrial Demands

Our cylindrical grinding wheels are engineered for exacting tolerances and customized to your specifications. With a choice of abrasive materials and bonding options, they deliver consistent results across automotive, aerospace, toolmaking, and general engineering industries. Each wheel is crafted to support smooth finishes, extended lifespan, and adaptability to a wide range of grinding machines.

Superior Material Composition and Bonding

Available with Aluminum Oxide or Silicon Carbide abrasives, our wheels are offered in both vitrified and resin bonds. This combination enables users to select the right chemistry and mechanical properties for specific applications, whether you require enhanced cutting speed, durability, or thermal resistance.

FAQs of Cylindrical Grinding Wheel:

Q: How do I select the right grain size and hardness for my cylindrical grinding application?

A: The correct grain size and hardness (H to N) depend on your material and desired surface finish. Coarse grits (24-46) are ideal for heavy stock removal, while finer grits (60-120) deliver smooth finishes. Match hardness to material typesofter wheels remove softer metals efficiently, while harder wheels suit tougher materials.Q: What materials are used in your cylindrical grinding wheels, and what benefits do they offer?

A: We use abrasive materials such as Aluminum Oxide (Al2O3) and Silicon Carbide (SiC). Aluminum Oxide is preferred for tougher metals, while Silicon Carbide is effective for non-ferrous materials and brittle substances, offering excellent cutting efficiency and durability.Q: When should I choose a vitrified bond over a resin bond for these grinding wheels?

A: Vitrified bonds are best for precision work, higher stock removal, and longer wheel life. Choose resin bonds when you need improved shock resistance, flexibility, or when grinding heat-sensitive materials.Q: Where are your cylindrical grinding wheels manufactured and exported from?

A: All our cylindrical grinding wheels are produced in China using advanced manufacturing processes and are shipped globally to serve clients in various industries.Q: What is the process for customizing the size and specifications of the grinding wheels?

A: Contact us with your precise requirements, including dimensions, abrasive type, bond, and grain size. Our engineering team will guide you through the selection process and manufacturing timeline to ensure the product matches your application perfectly.Q: How can cylindrical grinding wheels with high toughness benefit my production process?

A: High-toughness wheels withstand heavy applications and extendeduse, resulting in fewer wheel changes, consistent performance, and lower maintenance costs, enhancing your operations efficiency and productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Flexible Grinding Wheel

Minimum Order Quantity : 50 Pieces

Hardness : Yes

Shape : Round

Material : SS

Type : Flexible Grinding Wheel

Ball Grinding Wheel

Minimum Order Quantity : 3 Pieces

Hardness : Hard

Shape : Round

Type : Ball Grinding Wheel

Regulating Grinding Wheels

Hardness : Soft to Medium

Shape : Round

Material : Aluminium Oxide / Silicon Carbide

Type : Regulating Grinding Wheel

Backing : Reinforced Cloth

Toolroom Grinding Wheel

Hardness : Soft, Medium, Hard

Shape : Straight, Cylindrical, Dish, Cup

Material : Aluminum Oxide, Silicon Carbide

Type : Toolroom Grinding Wheel

Backing : None

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry