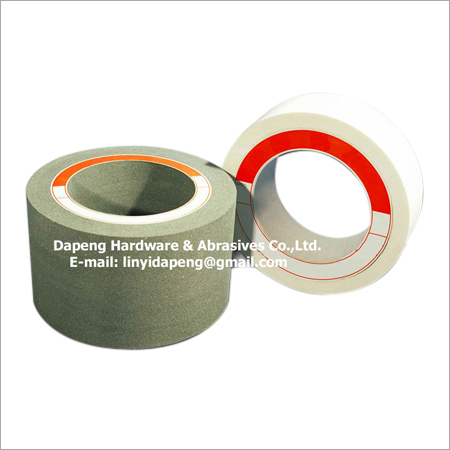

Roll Grinding Wheel

Roll Grinding Wheel Specification

- Shape

- Flat, Cylindrical

- Chemical Composition

- Al2O3, SiC, Bonding agents

- Backing

- Reinforced core

- Toughness

- High structural integrity for heavy roll pressure

- Bonding

- Vitrified / Resin Bonded

- Grain Type

- Coarse, Medium, Fine

- Hardness

- G to Z

- Material

- Aluminium Oxide / Silicon Carbide

- Type

- Roll Grinding Wheel

- Grain Sizes

- A24 to A100

- Rolls Size

- Customizable as per application requirement

- Strips Size

- Varies as per wheel diameter and width

About Roll Grinding Wheel

Backed by rich industry experience and in-depth domain knowledge, we are engaged in manufacturing, exporting and supplying the best quality Roll Grinding Wheel. This wheel is manufactured by our skilled professionals using excellent quality raw materials and sophisticated technology. Offered wheel is widely used for rough grinding, fine grinding and polishing of rolls. The provided wheel is made available in diverse specifications for our clients to choose from. Apart from this, we provide this Roll Grinding Wheel at pocket friendly prices to the clients.

Key Features:

- High tensile strength

- Durability

- Easy to fit

- Rugged construction

- Grinding wheels for rolls are made specially for steel firms and mills.

- The ground rolls have no vibrated veins and are of high precision and superior in quality.

- The max speed can be up to 50m/s.

| | Rough grinding | Fine grinding | Polishing |

| Diameter | 400 ~ 1100mm | 400 ~ 1100mm | 400 ~ 1100mm |

| Thickness | 25 ~ 100mm | 25 ~ 100mm | 25 ~ 100mm |

| Materials | A,WA,MA,PA,SA,GC,C | ||

| Grit Size | 36# ~ 60# | 80# ~ 150# | W14 ~ W5 |

| Bond Type | B1 | B2 | B3 |

They also can be supplied in required sizes,materials, grit sizes and types.

Superior Material Composition

Each roll grinding wheel is made using premium aluminium oxide or silicon carbide, combined with robust bonding agents. This composition ensures longevity and reliability, even under intensive grinding conditions. The chemical makeup delivers resistance to abrasion, supporting demanding industrial environments.

Customizable for Specific Applications

These wheels are available in varied shapesflat and cylindricaland sizes tailored as per client requirements. Strip dimensions and grain types, including coarse, medium, and fine, can be selected to optimize grinding processes, maximising compatibility with different roll types and materials.

FAQs of Roll Grinding Wheel:

Q: How are roll grinding wheels customized for specific applications?

A: Roll grinding wheels can be manufactured in a range of diameters, widths, and strip sizes, tailored precisely to the roll dimensions required by each application. Customers can specify their roll size and wheel shape (flat or cylindrical), ensuring optimal fit and efficient grinding.Q: What materials are used in the construction of these grinding wheels?

A: These wheels are made from either aluminium oxide (Al2O3) or silicon carbide (SiC), combined with bonding agents that provide high toughness and structural integrity. The composition is selected based on grinding needs and required performance.Q: Where are these roll grinding wheels typically used?

A: They are primarily employed in manufacturing facilities, steel mills, and other industrial settings for precision grinding of rolls. Their reinforced core and robust build make them suitable for environments that involve heavy roll pressure.Q: What is the process behind manufacturing roll grinding wheels?

A: Manufacturing involves selecting appropriate grains and bonding agents, pressing and forming the wheels into the desired shape, and curing through vitrified or resin bonding. This process ensures consistent hardness levels from G to Z and structural integrity for rigorous use.Q: How do these grinding wheels benefit industrial users?

A: They deliver high durability, consistent performance, and adaptability to various roll sizes. Industrial users benefit from increased productivity, reduced maintenance, and precision surface finishes on rolled materials.Q: When should I choose aluminium oxide over silicon carbide?

A: Aluminium oxide is preferred for steel and ferrous materials due to its toughness and longevity, whereas silicon carbide is chosen for non-ferrous metals and harder surfaces requiring sharper cutting action.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Ball Grinding Wheel

Minimum Order Quantity : 3 Pieces

Shape : Round

Hardness : Hard

Type : Ball Grinding Wheel

Flexible Grinding Wheel

Minimum Order Quantity : 50 Pieces

Shape : Round

Hardness : Yes

Type : Flexible Grinding Wheel

Material : SS

Centerless Grinding Wheels

Shape : Round / Wheel

Hardness : From N (Medium) to R (Hard)

Type : Centerless Grinding Wheel

Material : Abrasive Grain + Bonded Matrix

Grain Sizes : 46 Grit to 180 Grit

Cylindrical Grinding Wheel

Shape : Cylindrical

Hardness : H to N (varies by application)

Type : Cylindrical Grinding Wheel

Material : Abrasive (Aluminum Oxide or Silicon Carbide)

Grain Sizes : 24 to 120 Grit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry