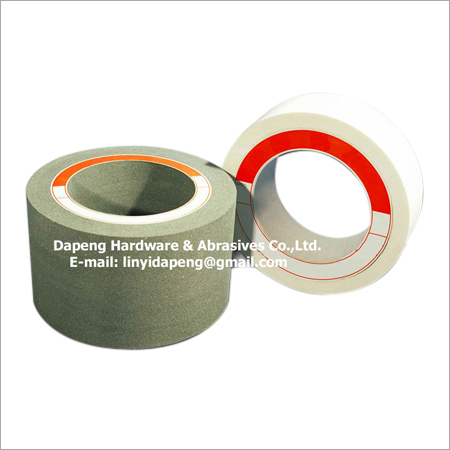

Centerless Grinding Wheels

Centerless Grinding Wheels Specification

- Bonding

- Vitrified, Resin Bonded

- Hardness

- From N (Medium) to R (Hard)

- Shape

- Round / Wheel

- Chemical Composition

- Abrasives, Binders, Fillers

- Grain Type

- Aluminium Oxide / Silicon Carbide

- Backing

- N.A. (Solid Wheel)

- Toughness

- High (Impact & Abrasion Resistant)

- Material

- Abrasive Grain + Bonded Matrix

- Type

- Centerless Grinding Wheel

- Grain Sizes

- 46 Grit to 180 Grit

- Rolls Size

- Diameter 100mm to 500mm

- Strips Size

- Custom and Standard Available

About Centerless Grinding Wheels

Centerless Wheel

We are a trustworthy manufacturer, exporter and supplier of a superior quality range of Centerless Wheel. In order to manufacture this wheel in conformity with international quality norms, our dextrous professionals utilize quality approved raw materials and cutting-edge technology. Our offered wheel finds application in various industries like, automobile, bearing, cutting tool, bar grinding and many more. In addition to this, we provide this Centerless Wheel in numerous sizes at market leading rates to our esteemed clients.

Key Features:

- Stable hardness

- Sturdy construction

- Dimensional accuracy

- Fine finish

Specifications:

- Diameter: 250mm ~ 750mm

- Thickness: 250mm ~ 600mm

- Hole: 127mm ~ 305mm

- Materials: A (brown aluminum oxide), WA (white aluminum oxide), PA (pink aluminum oxide), GC (green silicon carbide), C (black silicon carbide)

- Grit Size: 36#, 46#, 60#, 80#, 100#, 120#.

- 350 x 100 x 127mm

- 350 x 100 x 152.4mm

- 350 x 150 x 127mm

- 350 x 150 x 152.4mm

- 500 x 150 x 304.8mm

- 500 x 200 x 304.8mm

- 600 x 250 x 304.8mm

Engineered for Precision and Durability

Centerless Grinding Wheels combine advanced abrasive technology with a carefully formulated bonded matrix to deliver exceptional performance in demanding grinding environments. The wheels round, solid construction and range of grit sizes ensure adaptability for various machining requirements, while resistance to impact and abrasion assures durability during continuous high-speed operations.

Customizable Specifications to Suit Every Need

Choose from diameter options between 100mm and 500mm, with grain sizes from 46 to 180 grit and a selection of standard or customized strip sizes. Whether your application calls for vitrified or resin bonding, our centerless wheels offer the flexibility to meet specific requirements, maximizing workflow efficiency.

Global Reach, Consistent Quality

As a trusted exporter, manufacturer, and supplier from China, we maintain rigorous quality standards and supply to clients worldwide. Our expertise ensures every centerless grinding wheel delivers consistent performance and reliability, supporting your production processes wherever you are located.

FAQs of Centerless Grinding Wheels:

Q: How are centerless grinding wheels used in industrial applications?

A: Centerless grinding wheels are commonly used for precision grinding of cylindrical surfaces, eliminating the need for centers or chucks. The abrasive wheel removes material as the workpiece is supported by a blade and guided between the grinding and regulating wheels, making them ideal for rapid, accurate mass production of precision parts.Q: What is the manufacturing process for these grinding wheels?

A: These wheels are produced by combining abrasive grains (such as aluminium oxide or silicon carbide) with binders and fillers to form a bonded matrix. The mixture is shaped into round wheels, then hardened through vitrified or resin bonding processes to achieve the required toughness, hardness, and structural integrity.Q: When should I choose vitrified vs. resin bonded centerless grinding wheels?

A: Select vitrified bonded wheels for heavy-duty operations, excellent thermal stability, and consistent performance over long runs. Resin bonded wheels are preferred when flexibility, fast stock removal, or working on softer materials is required, as they offer a slightly softer structure and improved shock resistance.Q: What benefits do centerless grinding wheels offer over conventional grinding wheels?

A: Centerless grinding wheels allow for continuous feeding and rapid material removal, resulting in higher productivity levels. Their design supports uniform roundness and tight tolerance control without the need for center fixing, making them especially effective for high-volume, precision machining tasks.Q: Where are your centerless grinding wheels exported from, and do you support international orders?

A: Our centerless grinding wheels are manufactured and exported from China, supplied globally to a diverse range of industries. We support both small-scale and bulk international orders, ensuring consistent product quality and timely delivery to meet your operational schedules.Q: How do I choose the correct grain size and hardness for my application?

A: Select a coarser grit (such as 46) for rapid material removal and a finer one (up to 180) for smoother finishes and tighter tolerances. Hardness ranges from medium (N) to hard (R); choose according to the material being processed and the required finishharder wheels for tough materials and finer finishes, and medium for general-purpose grinding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Ball Grinding Wheel

Minimum Order Quantity : 3 Pieces

Hardness : Hard

Shape : Round

Type : Ball Grinding Wheel

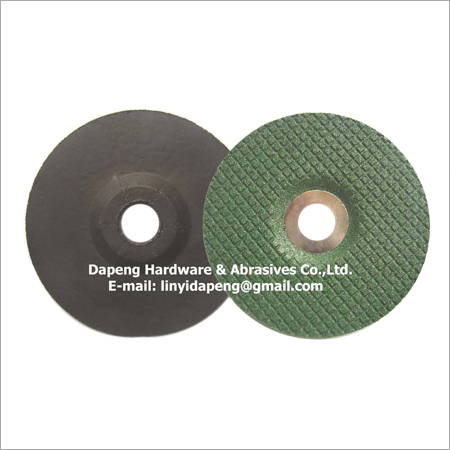

Flexible Grinding Wheel

Minimum Order Quantity : 50 Pieces

Hardness : Yes

Shape : Round

Material : SS

Type : Flexible Grinding Wheel

Regulating Grinding Wheels

Hardness : Soft to Medium

Shape : Round

Material : Aluminium Oxide / Silicon Carbide

Type : Regulating Grinding Wheel

Backing : Reinforced Cloth

Roll Grinding Wheel

Hardness : G to Z

Shape : Flat, Cylindrical

Material : Aluminium Oxide / Silicon Carbide

Type : Roll Grinding Wheel

Backing : Reinforced core

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry