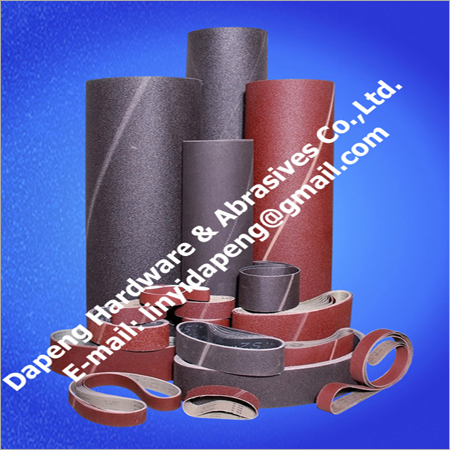

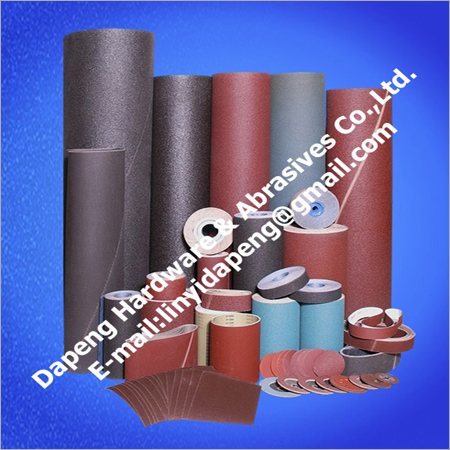

Coated Abrasives Belt

Coated Abrasives Belt Specification

- Toughness

- High

- Chemical Composition

- Aluminum Oxide, backing resins, bonding agents

- Hardness

- Medium to Hard

- Grain Type

- Aluminum Oxide

- Shape

- Belt

- Bonding

- Resin over resin

- Material

- Aluminum Oxide (Alox) on cloth backing

- Type

- Coated Abrasive Belt

- Grain Sizes

- P36 to P400

- Rolls Size

- 50 mm x 2000 mm, other sizes available upon request

About Coated Abrasives Belt

Abrasives Belt

For many years, we are committed to manufacture, export and supply an excellent quality array of Abrasives Belt. The belt provided by us is widely used for sanding and polishing plywood, shaving boards, trim boards, metallic or non-metal materials. This belt is precisely manufactured with the usage of premium quality raw materials and innovative technology in conformity with international quality standards. Apart from this, our offered Abrasives Belt is made available in numerous technical specifications at pocket friendly prices.

Key Features:

- Fine finish

- High strength

- Durability

- Resistant against abrasion

Other Information:

- Materials: Aluminum Oxide, Silicon Carbide.

- Bond Type: Resin over resin (R/R), Resin over Glue (R/G), Glue over Glue (G/G )

- Backing cloth: X-weight, Y-weight, J-weight

- Sanding and Polishing plywoods, shaving boards, trim boards, bamboo. woodware,and vineware.

- Sanding and Polishing complex surface of stainless steel plates, non-ferrous and ferrous metal plates and wood, etc.

- Polishing and napping metallic or non-metal materials.

Versatile Abrasive Belt Sizes and Customization

Our coated abrasives are available in the popular 50 mm x 2000 mm roll size to fit standard machines, but we also provide customization to suit unique specifications. Whether for small workshops or large-scale manufacturing, our flexible sizing accommodates diverse customer requirements efficiently.

Superior Material Composition for Lasting Performance

Engineered with aluminum oxide abrasive grains, these belts combine high hardness and excellent toughness with a resilient cloth backing. The resin-over-resin bonding enhances durability, ensuring optimal performance during heavy-duty processes across metals, wood, and composites.

Wide Range of Grits for Multipurpose Use

With grain sizes ranging from P36 (coarse) to P400 (fine), these abrasive belts are ideal for rapid stock removal, smoothing, and finishing. The range offers versatility for applications like deburring, surface preparation, and polishing, supporting a broad spectrum of industrial needs.

FAQs of Coated Abrasives Belt:

Q: How are coated abrasive belts manufactured?

A: Coated abrasive belts are produced by adhering aluminum oxide grains onto a durable cloth backing using resin-over-resin bonding techniques. The belts are then cut, shaped, and finished to precise dimensions, such as 50 mm x 2000 mm rolls, ensuring optimal performance and consistency.Q: What applications are suitable for aluminum oxide coated abrasive belts?

A: These belts are ideal for grinding, sanding, finishing, and deburring a range of materials, including metals, wood, and composites. Their varying grit sizes, from P36 to P400, accommodate both aggressive material removal and fine finishing requirements.Q: When should I choose a medium to hard abrasive belt for my process?

A: Medium to hard abrasive belts are best selected when handling demanding tasks that require durability and longevity, such as heavy stock removal or machining hard metals. Their higher hardness ensures sustained cutting performance and resistance to wear.Q: Where can I obtain custom sizes for my abrasive belt needs?

A: As a manufacturer, supplier, and exporter in China, we offer standard and custom belt sizes upon request. Simply provide your required dimensions, and we will tailor the abrasive belts to fit your specific machinery or application needs.Q: What are the benefits of using aluminum oxide as the abrasive grain?

A: Aluminum oxide offers high hardness, toughness, and cutting efficiency, making it suitable for both ferrous and non-ferrous materials. Its resilience ensures longer service life and sustained performance compared to other abrasive materials.Q: How should these abrasive belts be used for optimal results?

A: For best results, install the abrasive belt according to your machinerys specifications and select the appropriate grain size for your process. Proper tensioning, regular inspection, and timely replacement help maintain consistent surface finishes and extend belt life.Q: What is the typical process for exporting these belts internationally?

A: As experienced exporters, we package abrasive belts securely and handle all necessary documentation for international shipments. Orders are processed promptly to ensure timely delivery, with support provided for both standard and custom requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Abrasive Belts Category

Automotive Abrasive Belts

Shape : Belt

Hardness : Medium to Hard

Bonding : Resin over Resin

Grain Type : Coated Abrasive

Grain Sizes : P36 to P400

Strips Size : Various as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry