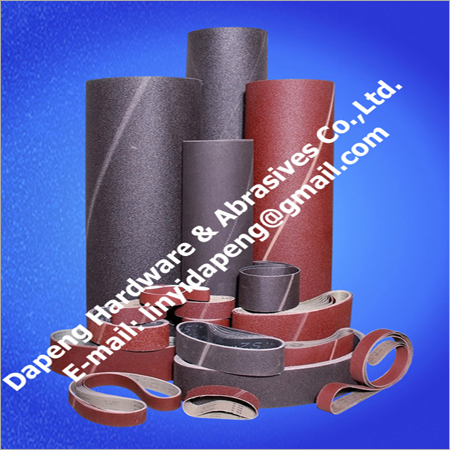

Automotive Abrasive Belts

Automotive Abrasive Belts Specification

- Bonding

- Resin over Resin

- Shape

- Belt

- Hardness

- Medium to Hard

- Grain Type

- Coated Abrasive

- Backing

- Cloth (Polyester or Cotton)

- Toughness

- High durability for automotive finishing

- Type

- Abrasive Belts

- Grain Sizes

- P36 to P400

- Rolls Size

- 50 mm x 2000 mm, 75 mm x 2000 mm, or custom sizes

- Strips Size

- Various as per requirement

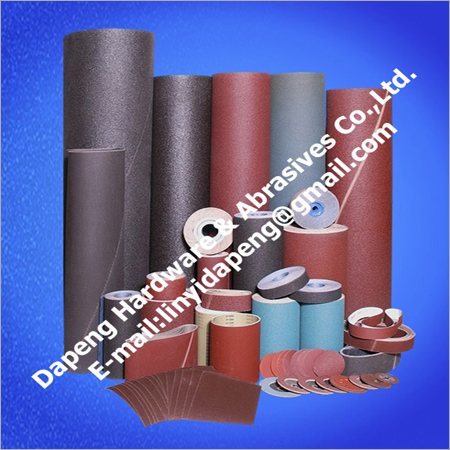

About Automotive Abrasive Belts

Automotive Abrasive Belts

With desire to cement our reputation in the market, we are engaged in offering the finest quality Automotive Abrasive Belts. Offered belts are manufactured using quality approved raw materials and sophisticated technology by our dextrous professionals in tandem with set international quality standards. These belts are widely demanded in several industries like automotive, automobile, and other industries all over the world. Moreover, we provide these Automotive Abrasive Belts in various specifications for our clients to chose from.

Key Features:

- Flawlessness

- Perfect finish

- High strength

- Low friction

- Materials: Aluminum Oxide, Silicon Carbide.

- Bond Type: Resin over resin (R/R), Resin over Glue (R/G), Glue over Glue (G/G )

- Backing cloth: X-weight, Y-weight, J-weight

Applications

- Sanding and Polishing Plywoods, shaving boards, trim boards, bamboo.Woodware and vineware.

- Sanding and Polishing complex surface of stainless steel plates, non-ferrous and ferrous metal plates and wood, etc.

- Polishing and napping metallic or non-metal materials.

Versatile Size and Customization Options

We offer automotive abrasive belts in standard roll sizes of 50 mm x 2000 mm and 75 mm x 2000 mm, as well as tailored dimensions and strip sizes as per specific application needs. This flexibility ensures a perfect fit for your machinery and processes, enhancing work efficiency and minimizing material waste.

Durable Construction for Demanding Tasks

Our belts feature a strong cloth backing (polyester or cotton) combined with a resin-over-resin bond, offering medium to hard hardness levels. This robust design delivers high toughness and longevity, making our belts ideal for rigorous automotive grinding, sanding, and polishing operations.

Wide Range of Grits for Precise Finishing

Choose from an array of grain sizes, from coarse P36 for rapid material removal to fine P400 for smooth polishing. This versatility allows precision finishing on automotive parts, achieving the desired surface texture and preparing components for painting or assembly efficiently.

FAQs of Automotive Abrasive Belts:

Q: How do I determine the right abrasive belt size for my automotive machinery?

A: The correct belt size depends on your machines drum or platen dimensions. We offer standard roll sizes (50 mm x 2000 mm, 75 mm x 2000 mm) and provide custom sizes to suit your specific equipment and processing needs, ensuring optimal contact and performance.Q: What is the recommended process for installing and using these automotive abrasive belts?

A: For best results, ensure the belt is properly fitted onto the equipment without excessive tension or slack. Start with a coarse grit to remove surface material, then progress to finer grits for finishing. Regular inspection will help avoid belt breaks and maintain consistent finishes.Q: When should I choose a specific grit size, such as P36 versus P400?

A: Select coarser grits like P36 for heavy material removal and initial shaping, while finer grits like P400 are ideal for final surface smoothing, polishing, or preparing parts for painting. Matching the grit to your job improves efficiency and surface quality.Q: Where are these automotive abrasive belts suitable for use?

A: Our belts are ideal for automotive manufacturing plants, repair workshops, and body shops where surface finishing, sanding, or polishing metal and composite vehicle parts is required. Their high durability makes them reliable even in demanding industrial environments.Q: What benefits do resin-over-resin bonded, cloth-backed abrasive belts offer?

A: This construction provides enhanced bond strength and resistance to heat, minimizing the risk of premature wear or grain loss. The cloth backing allows for flexibility while maintaining toughness, delivering a longer lifespan and consistent finishing across automotive surfaces.Q: Can these abrasive belts be used for both metal and non-metal surfaces?

A: Yes, these belts are designed for versatile automotive applications, suitable for processing both metal and composite surfaces. Their high-durability grain and robust bonding ensure effective cutting and finishing regardless of the substrate.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Abrasive Belts Category

Coated Abrasives Belt

Material : Aluminum Oxide (Alox) on cloth backing

Toughness : High

Chemical Composition : Aluminum Oxide, backing resins, bonding agents

Rolls Size : 50 mm x 2000 mm, other sizes available upon request

Grain Sizes : P36 to P400

Type : Coated Abrasive Belt

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry