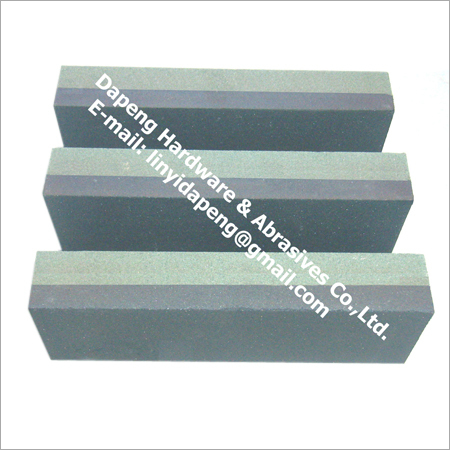

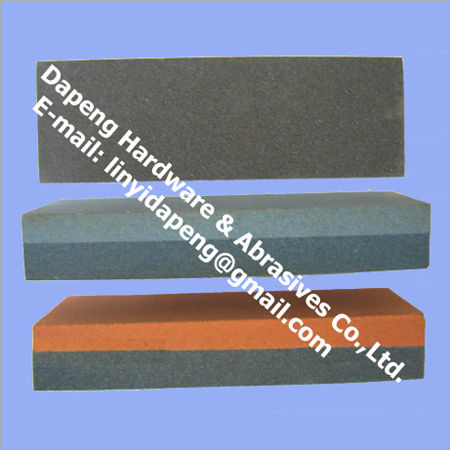

Tool Sharpening Stone

Tool Sharpening Stone Specification

- Function

- Sharpening Edges of Tools

- Motor Power

- Manual Operation

- Surface Finish

- Coarse and Fine Grit Sides

- Power Source

- Manual

- Tool Type

- Sharpening Stone

- Material

- Abrasive Stone (Silicon Carbide/Aluminium Oxide)

- Shape

- Rectangular

- Dimension (L*W*H)

- 200 mm x 50 mm x 25 mm (Approx.)

About Tool Sharpening Stone

We are counted amongst noteworthy manufacturers, exporters and suppliers of an excellent quality Tool Sharpening Stone. The provided stones are manufactured with high precision under the strict supervision of our adroit professionals using supreme grade raw materials and sophisticated technology at par with international quality standards. Offered stones are widely used to sharp and grind the edges of steel tools. Besides, clients can avail these Tool Sharpening Stone from us in variety of specifications at market leading prices.

Specifications:

| Size | 6" x 2" x 1" | 150 x 50 x 25mm | Fine/Coarse |

| 8" x 2" x 1" | 200 x 50 x 25mm | Fine/Coarse | |

| Material | A ( brown aluminum oxide ), WA ( white aluminum oxide ) | ||

| C ( black silicon carbide ),GC ( green silicon carbide ) | |||

They also can be supplied in required sizes,materials, grit sizes and types.

Dual Grit for Precision Sharpening

Experience versatile sharpening with coarse and fine grit sides, allowing you to restore dull edges and finish blades with a smooth polish in one convenient tool. Perfect for professional and home applications, this stone adapts to various tool sharpening needs.

Durable Construction, Effortless Operation

Built from resilient silicon carbide and aluminium oxide, this stone is designed to withstand repeated use. Its manual operation provides complete control over the sharpening process, making it suitable for users of all experience levels.

Adaptable to Wet or Dry Use

Sharpen your tools according to preference or requirementuse the stone wet with water or oil to reduce friction and extend stone life, or employ it dry for quick touch-ups. Flexibility in application translates to extended usability and user convenience.

FAQs of Tool Sharpening Stone:

Q: How do I use the sharpening stone for best results?

A: Begin by placing the stone on a stable surface. For improved results and longer stone life, lubricate with water or oil, though it can also be used dry. Start with the coarse side to reshape or fix dull edges, then finish with the fine side for honing and polishing. Maintain consistent angles, applying light, even pressure throughout the process.Q: What types of tools can I sharpen with this stone?

A: This sharpening stone is ideal for chisels, knives, blades, and most manual cutting tools. Its dual-grit surfaces support both initial sharpening and finishing touches, making it versatile for various workshop and kitchen tools.Q: When should I use the coarse side versus the fine side?

A: Use the coarse side for repairing nicks, reshaping edges, or sharpening very dull tools. Switch to the fine grit for refining the edge, removing burrs, and achieving a polished, razor-sharp finish.Q: Where should I store the sharpening stone to ensure longevity?

A: Store the stone in a dry, cool place to prevent moisture absorption or damage. Avoid high humidity areas, as excessive moisture may compromise the abrasive materials integrity.Q: What is the sharpening process with this stone?

A: Secure the stone, select the appropriate grit, and choose between wet or dry sharpening. Hold the tool at a consistent angle against the grit, moving back and forth evenly. Alternate sides as needed, then wipe clean after use.Q: Can I use both water and oil on this sharpening stone?

A: Yes, this stone is compatible with both water and oil as lubricants, depending on your preference. This flexibility helps reduce friction, enhance sharpening effectiveness, and lengthen stone lifespan.Q: What are the benefits of using a manually operated sharpening stone?

A: Manual operation provides precise control over sharpening angles, minimizing the risk of damaging tools. It requires no electrical power, making the stone portable, reliable, and suitable for any setting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry